In late April of this year (2020) I started to review where I had left off with the build. Due to the Coronavirus work has slowed and hours reduced. I found myself with more time on my hands, working only 3 days a week. More time for yard work and projects. When I bought the .308 barrel it came 6 inches longer than inticipated. Rather that shortening the barrel, I made the decision to add an extension as a longer barrel adds velocity.

I had a hard time finding a piece of aluminum for the extension. Every vendor could order it in and I finally found a shop that had a length and was able to get a few inches for the extension. My next issue was being able to lathe the larer tube. My little 7X14" lathe cannot chuck the larger diameter. Thankfully a coworker allowed me to use his new lathe he had at home, it has 1.5" bore.

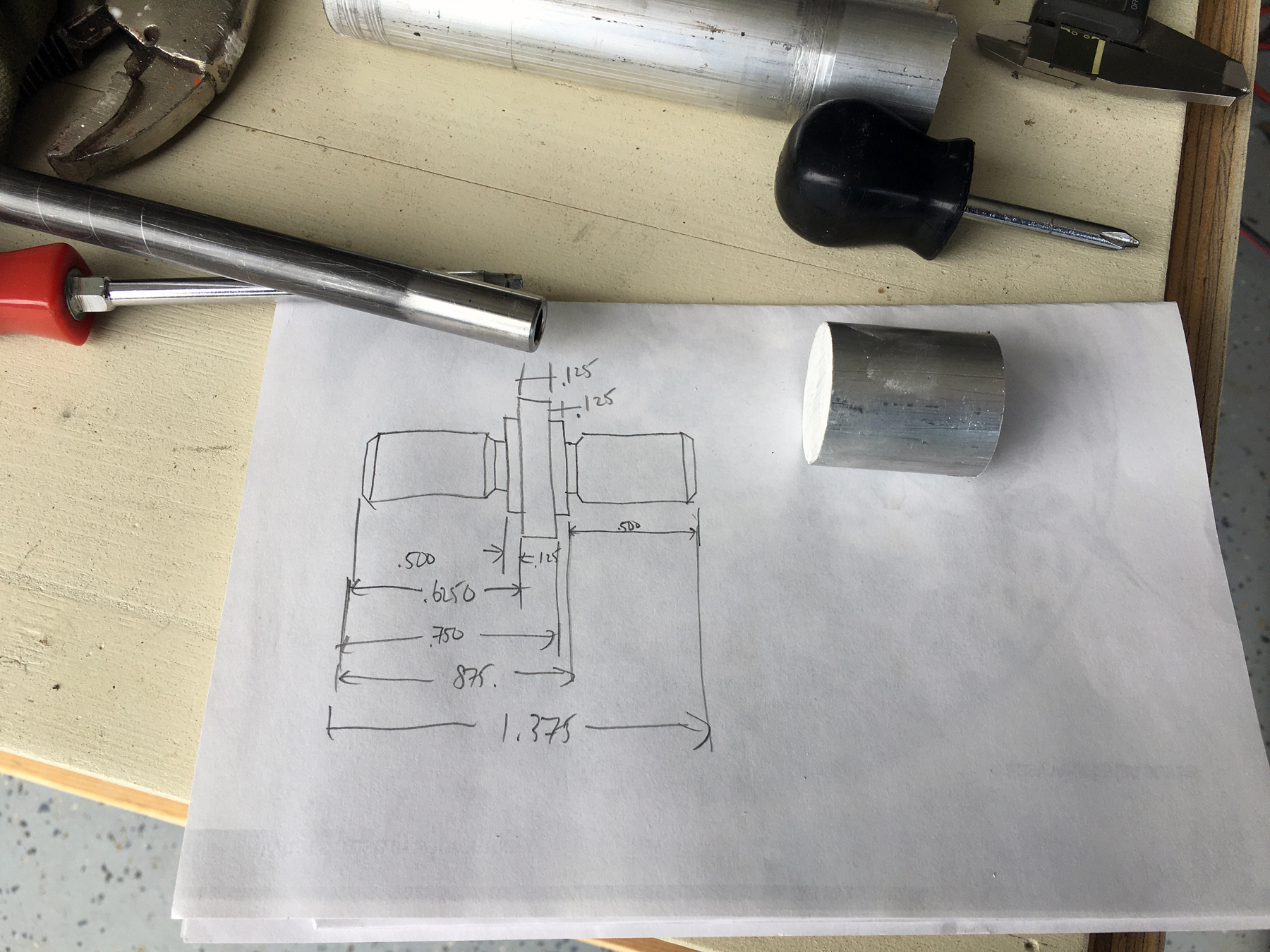

Sketched a drawing to have some measurements to follow while lathing. Wanted to keep the adapter as short as possible but with neough thread to be able to hold the tubings tightly. Went with 18 TPI (threads per inch) on the thread.

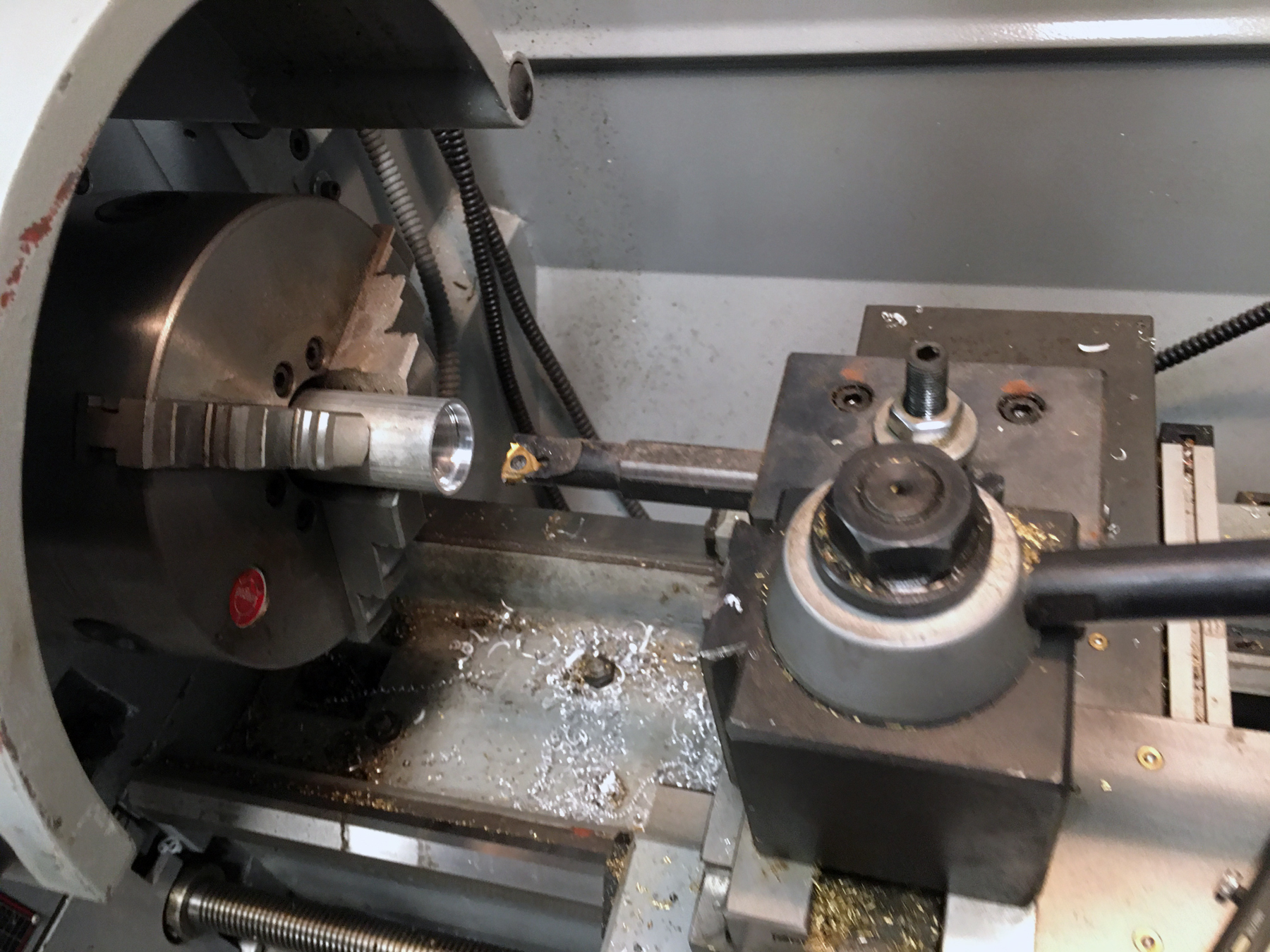

Prepping the adapter for thread cutting, first one side and then the other.

Finally threaded both sides of the adapter. Threading on the little lathe isn't that easy. I wanted 16 TPI but couldn't find a 40 tooth gear that should be with the set. Keeping the thread half nut engaged proved to cut better thread as well rather then engaging at the correct number.

The end cap was also threaded. Next step was threading the internal tube to accept the cap and adapter.

Next two pictures are using coworkers lathe to thread the internals. Nice having access to a large lathe.

Having lathed the internal threads I again used my little lathe to finish the parts.

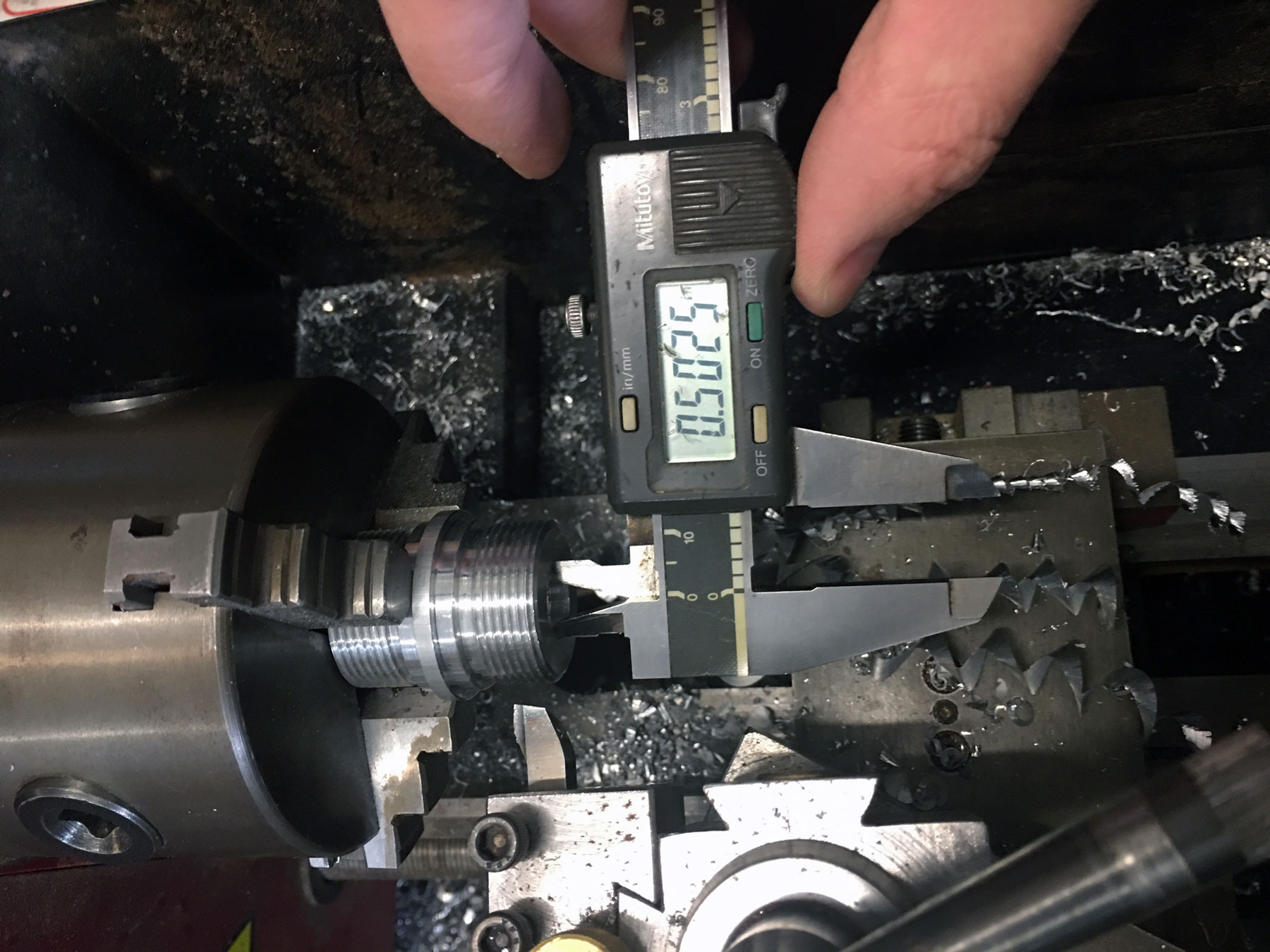

The tubing, adapter and end cap all fit well. Next the parts all needed a through hole for the barrel. The barrel is .505" and the adapter had to slide over it. The end cap not only serves to guide the barrel but is also the barrel end stop to keep it in place.

Lathe the endcap to fit the barrel and a recess to also stop the barrel from launching out when fired. I had to setup a few times to remove the right amount of material for everything to align and fit snug.

Once the correct distance was established a "crown" was lathed onto the exit end. May need further refinement.

A few more test fits, adjustments and assembly. The exit diameter on the end cap is a few thousands of an inch larger than the caliber.

Reaching this point of the build my anxiety was up, I had to test at least one shot. I had a simple mold I made long ago to pour 1/2" lead shaft for experiments. This helped to quickly make a test slug.

With a safe place to test I filled the air reservoir to 1500PSI and took one shot. The 2 X4" I used had a knot on the back side, and I am sure the slug would have travelled further if the knot hadn't been there. Regardless, the power is there as seen by the depth of penetration.

After the test I should have clued in that that valve was dumping all the air. Thinking it was just that the air pressure in the tank was not high enough, I left it. I will remark further on the outcome on page 4.

More to come as I work on additional content, page 4 will be test firing the rifle and related.