As mentioned elsewhere I hadn't posted this build and I am only recently catching up with posting content on my site. 2019 is a blurr as far as airguns

are concerned. I haven't been out shooting or building since 2018. The biggest reason was that my wife was diagnosed with ovarian cancer back in October of

2018. In 2019, end of February she under went successful surgery to remove the two tumors and then endured eighteen weeks of chemotherapy, once a week. She is

doing really well despite what could have been.

Sometime last summer I did pickup the .308 build but didn't have the enthusiasm or motivation to work on much. It was then that I noticed that the cocking

effort was way to high along with the closing the action. Something was wrong. I started taking the rifle apart and discovered the screws I had made to

control the breech travel had bent. The bent screws where galling the aluminum tube internal diameter. I decided to make new hardended screws.

First picture are the two screws that were damaged from cocking and triggering the rifle. My guess was that the travel was to limited and the hammer/spring force when released caused the screws to bottom out in the slot and bend.

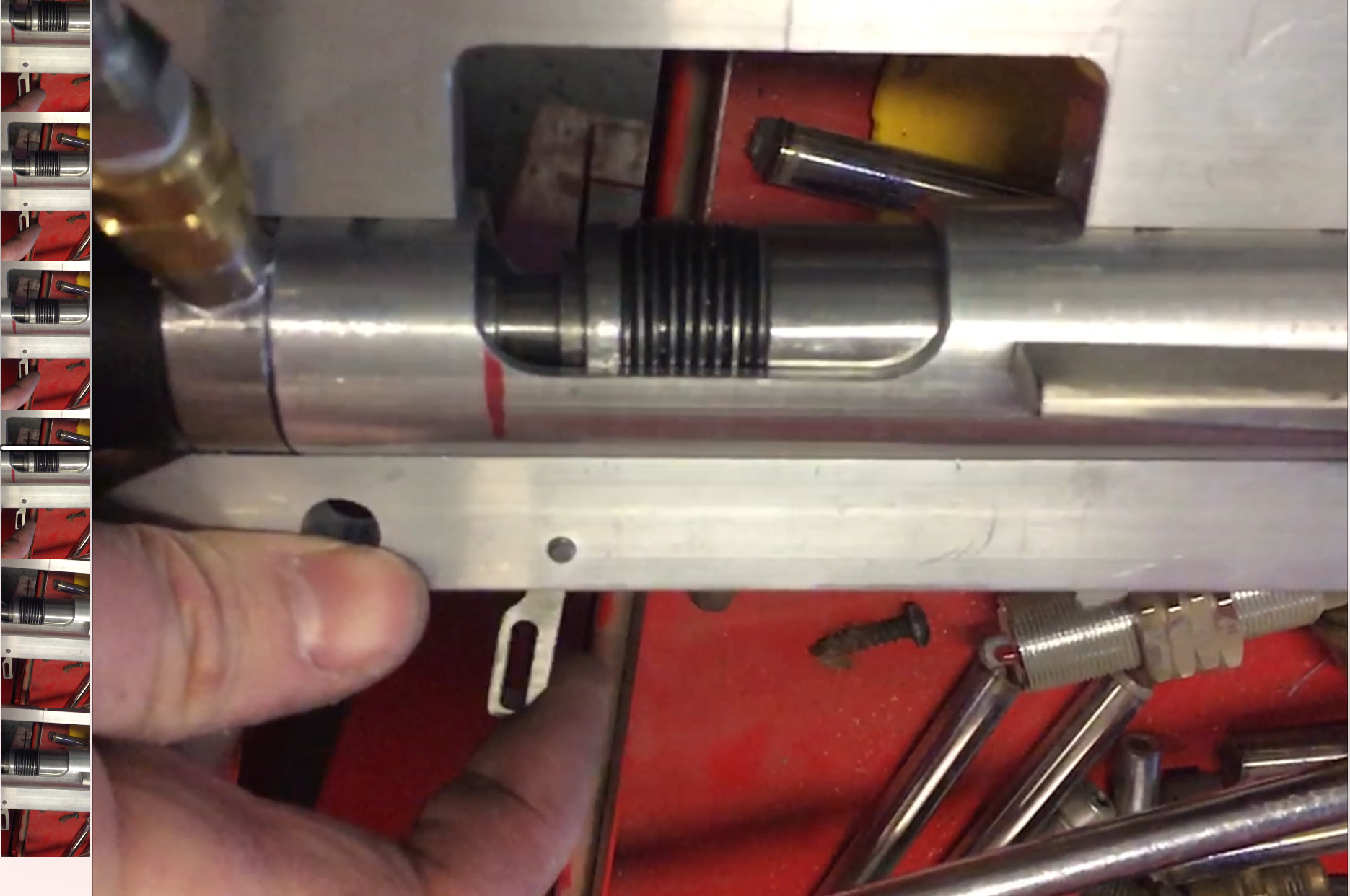

The following two pictures show the galling or scratches that were relayed to the wall of the aluminum tubing. The screw heads dug in fairly deep and hence caused the cocking effort to be rather difficult.

Two new screws were made, heat-treated and fastened back into the breech.

Initially everything seemed fine. I tested fired the action a few times and didn't take long before issues once again presented themselves. Cocking effort became difficult and then found the head of a screw when I tilted the rifle tube. The heat-treat was good as shown by the fine grain size of the break but I should have tempered a few times to remove the brittleness of the steel.

While I had all the parts disassembled, some internal parts needed attention. Minor scratching was seen on the outer diameter of the internal spring/hammer tube. Since the OD guides inside the aluminum tube the entire length doesn't have to be the same diameter. Thankfully my little lathe is just large enough to be able to lathe these parts.

Another round at making screws for the breech. These screws are made of O1 drill rod. Oil hardening steel. I lathed the rod to the screw size.

It is much easier cutting thread on small item with a die than using the lathe. Much quicker as well.

The rod was then cut to rough size and milled to the desired thickness on the mill. I made a small grooving tool to add the screw slot and proceeded to add the slot.

Test fitted the screws in the breech. Thankfully the threads in the breech weren't damaged but chased them with a tap to make sure.

Here's a video showing the heat treat of the screws. If you are going to quench any steel in oil, ensure the room is well ventilated.

Video of tempering the screw.

With the screws completed, the parts of the rifle were once again assembled. Here you can see the slots for the breech travel were increased to keep any force from the hammer impact against the valve and cause the screws to bottom out against the slot.

The speed at which the hammer impacts the breech and this opening the valve happens so fast, the naked eye doens't catch it. Using the SLO-MO video capture on the Iphone allowed to see the entire travel of the valve. This helped to determine just how long the slots needed to be to keep the screws frmo bottoming out and being broken again.

More to come as I work on additional content, page 3 will be current build progress (May, 2020).